by Steve Schneider

A year ago, Saga Communications owned two stations in Portland, Maine, Classic Hits WMGX-FM and News/Talk WGAN-AM. The company had recently purchased the stations, and with that purchase came changes for the better. Saga moved us from a rickety, run-down Victorian house to a new, 18,000 square foot broadcast facility. Nearly everything was new, right down to the drawer dividers. The News/Talk studio seated six comfortably, and we had three production rooms including oversized 8- and 4-track suites. We traded our mail table for a mail room twice the size of many air studios. This was nirvana -- plenty of space for everybody and everything. Then came "The Announcement" telling us that Saga had purchased two more stations, and that they were coming to live with us.

It was exciting news that presented us with new challenges. Although we were adding two stations, we would only add five new people: a Program Director, three Air Personalities, and a Traffic Manager. At the same time, we lost a few part-timers who were not to be replaced. One new station, Oldies 100.9 WYNZ, moved into the 2-track production room. The other, Talk Radio 970 WZAN, moved into what had been a spacious album storage room. We gained valuable production talent, but went from two stations with three production rooms to four stations with two production rooms.

Another difficulty was paperwork, especially on the business and sales sides of the station. Even with two stations, too many things were slipping through the cracks, getting lost or misplaced. There was no single, universal system for keeping track of copy, time orders, and production orders. Copy would often arrive late, multi-voice spots would have to be done at the last minute, and agency tapes would get misplaced -- the usual Production Director character builders. With two stations, some frantic searching and begging would typically get the Account Exec out of a jam. But, with four stations, things had to move more quickly and smoothly. The bottom line was that we had to figure out how to do more with less and do it faster, and that meant getting organized.

Our first step was to make sure that all of the managers agreed that the general problem was one of organization. This is important. If we'd had people or facilities problems, our overall direction would have been different. Make sure that all of your managers or department heads are on the same page. Talk to each other. Find out what kinds of problems other people have to deal with and how they relate to you. You'll start to hear a pattern that goes something like this: "We never (insert complaint). I wish we could (insert idea/solution)." Write down ideas. After a few weeks, everyone will have a pretty good feel for what's bothering them about the status quo and what they'd like to see done differently. Then it's time for the first manager's meeting.

The line-up at our first meeting included the General Manager, all of the Sales Managers and Program Directors, the Business Manager, Marketing Director, and me, the Production Director. We spent two hours telling each other what we'd like to see happen, discussing how a possible change would affect other departments and then deciding "Yea" or "Nay." Always in front of us was the question: "Will this change make us better, faster, and more accurate?" By the end of the meeting, everyone was enthusiastic about the changes we were going to make. What follows are some of the changes we've implemented.

Circular Paperwork Flow: We found that so-called "short cuts" take a lot of extra time. When a salesperson goes to production with a last-minute spot to produce and says, "I just got this. Can you do it by 6:00 tonight?" it creates a domino effect of interruptions. The Production Director stops what he or she is doing to deal with the problem, which may mean assigning the spot to someone else, who stops to deal with the problem. Traffic stops to deal with the problem and maybe the Sales Manager as well. That's three or four people derailed by one client for one station. Now, multiply that slowdown by your total number of salespeople and radio stations.

Our solution to "short cuts" was to eliminate them. Now, when a salesperson gets an order, a production order must be written up and given to traffic with the time order. Both have to be together and both must go to traffic and nowhere else. If copy is available, then that too is included and given to traffic. Traffic will not assign cart numbers to the carts or to the log until copy is IN HOUSE. If copy is not available, then the time order is entered, but the production order is held by traffic. This means that I don't see a piece of production until the order is entered, the production order is done, and the copy and/or tapes are physically at the station. Does this require some planning ahead by the salespeople? Yes.

Once I have copy and/or tapes and a complete production order, I'll assign it out or do it myself. When finished, the carts go into the studio(s) and the production order and copy go back to the salesperson. It's a circular flow -- sales to traffic to production to sales. We save every spot we produce on DAT master tapes, and we write the tape and cut numbers on the production orders as the commercials are completed. When everything is done, the salesperson has their copy of the time order, the production order, the copy, and the master tape number for each spot produced. The contract number is written on the production order by traffic before being sent to production, so everything can be easily cross-referenced. It works, but only if we are religious about fixing broken links immediately. If traffic sees that a salesperson hasn't filled out an order correctly, it goes back to the salesperson to be done right. If a salesperson sees that a production person didn't write the master number down on the production order, they kick it back to me, and I get it done.

Spec spots are handled the same way, except that instead of a cart going to the studio, a cassette goes to the Account Exec. The production order has a place to note whether or not the spot is a spec. The definition of "spec" can get a little hazy, so here's what we came up with: NO WRITTEN TIME ORDER EXISTS -- The spot must be a spec. WRITTEN TIME ORDER DOES EXIST -- The spot cannot be a spec. By keeping the definition rigid, the producer will always know what to do with the finished production. Either it goes into the studio on cart or back to the Account Exec on cassette.

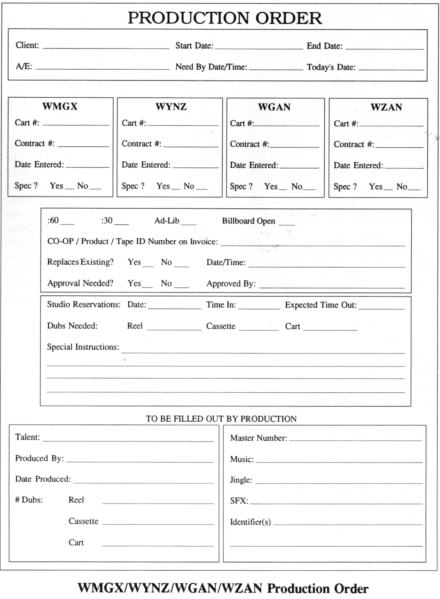

Production Order: If you have multiple radio stations with separate production orders for each station, stop the madness. Consolidate. I've included a sample of the production order I came up with to serve all four stations. There's room for cart numbers and contract numbers for each station, plus various other bits of information including studio time requests for visiting clients and a section for special instructions. At the bottom is a place for the production person to sign and date the completed order and note the master DAT tape and cut number and any music or sound effects used. This comes in very handy when a client comes back three months later and says, "I want the spot to sound exactly like it did before, except now the price is ten bucks more." It also makes it easy to keep track of the music beds used by each client, so we can maintain a consistency in music when appropriate.

Each manager contributed to this production order. It contains the information that's important to each person who sees the order, and it allows for fast cross-referencing. I think this production order plays a key role in making things run smoothly because it's a one page document that ties traffic, sales, and production functions together. I did it on a 386 clone running Pagemaker, and we photocopy the orders as we need them.

Production Distribution: A couple of weeks ago, we got an order from Dodge that required ten different spots to run in some incredibly sophisticated whiz-bang rotation that only an agency could dream up. It meant ten separate carts. That's a lot when you have one station, but when the buy comes down for three or four stations, you can end up with a three foot stack of carts for one client.

With that in mind, I think it's important to be as fair as possible when assigning production. I keep an assignment sheet (done on Pagemaker) which I use to keep track of who gets what for production. I try to keep a balance so that no one feels overwhelmed or buried and so that everyone has his or her share of creative production to do, as well as the necessary dubbing. I ask the production people if they have enough time to get everything done, and I tell them to let me know if there's a time problem. I find that by doing this, the production people are more likely to help out, especially in a pinch. It's not uncommon for a production person to finish up and ask if there's anything else they can do. That kind of cooperation is invaluable at any station, but even more so when there are multiple stations.

Production Training: When a new system like ours is put into place, it's important to make sure that all of the production people understand it. The changes we put in place affected them the least -- they had a different production order to look at and the finished production sometimes went to a different place. But by explaining the reasoning behind it, they could see that the new system would mean less last-minute production, fewer salesperson panic attacks, and fewer problems due to lack of time and forethought. I held "seminars" in which I explained our new organizational system and the new DAT mastering system. I then followed up with a brief memo and asked people individually over the next few weeks if there were questions or problems.

Traffic: We have one Traffic Director handling our two AM talk stations and another Traffic Director handling the two FM music stations. They work separately, but because time buys can be placed on any combination of the four stations, they need to be in close communication. Suppose, for example, that twenty dubs were done last night for Dodge to air on the two talk stations. The next day, the same tapes show up with a production order for twenty more carts to run on the two music stations. It's a pain in the butt. It's much easier to do all of the dubs for all of the stations at once, schedule permitting. To make that happen, each Traffic Director needs to know what's coming up on all four stations.

In the past, we had a problem with salespeople in the air studios, either pulling a cart to play for a client (and then forgetting to put it back) or talking with a jock about an upcoming promotion, the Celtics game, or whatever. Account Execs are no longer allowed in the air studios, and the only people who can pull carts out of the air studios are myself or the two Traffic Directors. That's another aspect of eliminating "short cuts."

Time: Doing just about anything for four stations takes more time than doing it for one or two. Sales has to understand this and work ahead as much as possible. There will always be last-minute orders and production, but with some effort, a lot can be done to get ahead. Ever notice how things get done ahead when there's a three day vacation weekend?

To prevent log jams at the end of the day for both traffic and production, we've developed these time lines:

1. All orders to run tomorrow must be in to traffic by noon today.

2. All copy to start tomorrow must be in to traffic by 3:00 p.m. today.

3. Creative or complex single-voice production requires 48 hours lead time before airing.

4. Multi-voice spots require 72 hours lead time before airing.

It took and is still taking some time to educate our clients concerning our time frame. But, by explaining the complexities of operating four stations, we have found most to be very understanding. There are always going to be exceptions; that's a given. But, the goal is to try to reduce the exceptions (read: multiple domino-style interruptions) to a minimum.

Another time consideration is promo and sweeper production for four stations. To do promos and sweepers well requires a lot of time. I'll spend four hours on a good promo, and a series of sweepers takes just as long. Obviously, one person could easily do nothing but promos and sweepers day in an day out for four stations. That might be an option if there were also an Assistant Production Director to take care of the organizational duties and some of the commercial production load. At Portland Radio, we have one Production Director and a number of good production people, so we split promo and sweeper production up this way: WMGX promos/sweepers done by me; WGAN promos/sweepers done by WGAN PD and/or Morning Show Producer; WYNZ promos/sweepers done by WYNZ Night Air Personality; WZAN promos/sweepers done by WZAN Morning Show Producer.

Doing promos and sweepers is part of those people's production schedules, and I make allowances in their commercial production load to accommodate the time needed to produce good station image and promotional pieces.

Copywriting: I've worked in single station situations where I did the promos, the sweepers, the copywriting, the promo writing, commercial production, and so on. With four stations, something has to give, so I do no copywriting at all. We use a copywriting service, and our salespeople also write copy. I've worked with the salespeople on writing techniques and held writing and brain-storming sessions, but when it comes to actually writing spots, I just don't have time. It may not be an ideal situation, as far as getting top quality copy to produce for our clients, but without a part- or full-time copywriter, it's about the only way to go. I would say copywriting is a weak link we still need to deal with.

Limitations: If you find yourself in a situation where all of a sudden you have another one, two, or three radio stations to handle, here are a few things to keep in mind:

1) You need to have a crystal clear description of your job responsibilities from your Program Director and GM. Make sure they can tell you what your on-the-job priorities are in one paragraph or less. For example: "Make sure all production is delegated and done correctly and is in the air studios when it's supposed to be. Keep production organized and running smoothly. Spend 12 to 15 hours doing the best station promos and sweepers possible, then delegate the rest." Or, it could be, "Do fifty percent commercial production, forty percent promo production, and ten percent paperwork." The main thing is to make sure you're doing what upper management thinks needs to be done. Stay focused and don't get sidetracked or bogged down.

2) Depending upon your job description, you will most likely become more of a manager and less of a doer. That'll mean delegating more and producing less. It's okay. Don't feel guilty about letting go of some things. You cannot possibly do all of the production for three or four stations yourself, unless you choose to live life as a 90 hour-a-week, Twinkie-eating, chain-smoking burnout.

3) Do not flatter yourself by thinking that no one else can do production as well as you (even if it's true). As the overall work load increases, you will be better off in the long run assigning some of the pet projects out to others so that they can develop their production skills. As others get better at production, you as a Production Director will have less of a burden. And your production people will have more interesting things to do, not just dubs. Invest the time to train them and show interest in their development. You'll get every hour back, and your production staff will keep getting stronger, which means the next time there's last minute production, you won't be the only one who can handle it.

4) Keep your sense of humor.

To sum it up, we've found that a rigid paperwork flow coupled with a highly functional production order do a lot to keep us organized. Get rid of as many forms as possible by consolidating. Organize your filing so everything concerning an order is returned to and kept by the Account Exec. Invest the time needed to train your production people, and then delegate work to them as fairly as possible. Have a clear understanding of what your priorities are, and most of all, make sure everyone agrees on the advantages of the new system and wants it to work. When it all clicks, you'll get everything done and be out of work in time to see the sun still shining.

♦