by Steve Cunningham

The lowly compressor is one of the most ubiquitous outboard devices in any production room. It’s also one of the most misused devices in the production room. When used properly, compressors can make a signal seem louder than it actually is, can minimize the wide changes that occur when the talent lacks proper mic technique, and can improve the intelligibility of speech that ends up being rerecorded or dubbed several times. But overused, compression can cause audible artifacts like pumping and breathing, can muddy the overall sound of a track, and can generally squeeze all the life out of an otherwise good performance.

What Does a Compressor Compress?

A compressor’s basic function is to reduce dynamic range, which is the difference in dB between the loudest and softest sounds that pass through the recording chain. Simply put, a compressor is a processor whose output level increases at a slower rate as its input level increases.

Compressors usually have four main controls — Threshold, Ratio, Attack Time, and Release Time, each of which can affect the others. In addition, most have an input level control and an output level control, which is sometimes called “Make-Up Gain”.

The Threshold control sets the level at which compression begins. Below the Threshold, a compressor (ideally) acts like a straight piece of wire or a linear amplifier. Whatever goes in comes out unchanged, except perhaps for a shift in overall level. When the input increases by 6 dB but is still below the Threshold, the output also increases by 6 dB. But when the input level reaches the Threshold, then the compressor begins reducing its output level by an amount determined by the Ratio control.

The Ratio control establishes the proportion of change between the input and output levels. The ratios are either completely variable, or there will be several selectable points between ratios of 1.1:1 and ƒ:1. If you set the compression Ratio to 2:1, then a 6 dB increase of the input signal will cause the output to increase by only 3 dB.

Looked at another way, if the compressor’s output changes by 3 dB when an above-Threshold input changes by 6 dB, we say that the Compression Ratio is 2:1. If we want a peak that comes in at 10 dB above the Threshold to come out at a level that’s only 2 dB above Threshold, we need to compress with a Ratio of 5:1.

This example represents 8 dB (10 minus 2) of gain reduction. This is of course an average, since the actual amount of gain reduction at any instant varies with the input level at that instant. When someone says, “I compressed the VO by 2 dB,” they mean that they applied light compression, where most of the peaks didn’t get more than 2 dB of gain reduction. This amount is typical for a VO talent who has good mic technique.

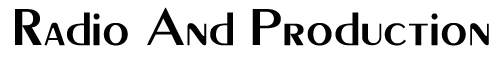

If we never want the output level to exceed the Threshold level, the compression Ratio must approach infinity (considered 10:1 or greater). A large change in input level over the Threshold will result in a very small change in output level. In this case, our compressor becomes a limiter, as the output level is limited to the Threshold level (see figure 1).

Different Slopes For Different Folks

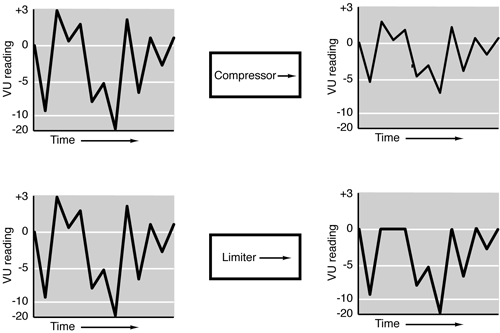

Figure 2 illustrates the basic action of a compressor graphically for several ratios. The slope of the line represents the gain. Notice that the line changes its slope at the point where we’ve set the Threshold, in this case, at 0 dB. What makes a compressor a compressor is the fact that its gain changes from unity to some lower gain when the input level exceeds the Threshold. Below the Threshold level, the compressor has a gain of 1. For every dB change in input, there’s a corresponding change of 1 dB in output. Above the Threshold, the gain is lower. Look at the 2:1 line. Note that with 10 dB change in input, we get only 5 dB change in output, a Ratio of 2 to 1.

The point at which the slope of the line changes is called the “knee.” A compressor is said to have a “hard knee” characteristic when the slope changes abruptly as in this graph. Some compressors have a “soft knee” characteristic in which the break isn’t a sharp change of angle, but is rounded so that the gain change is gradual over some range of input. dbx holds the trademark on the term “over easy” to describe their brand of soft knee compression. The gain change of a soft knee compressor actually begins somewhere below the Threshold level and gain continues to decrease to its final value at some input level beyond the Threshold. A hard knee tends to do better at catching transients while a soft knee characteristic tends to be less obtrusive. Some compressors let you switch between hard and soft knees.

A compressor doesn’t know what’s coming at it until it happens, so it needs time to figure out how much gain reduction is needed. This is called the response time, and it is a function of the way the input level is detected. It’s fixed as part of the compressor design and is one of the things that contributes to the compressor’s personality.

The Attack Time controls how long it takes for the compressor to reach full gain reduction when triggered by an over-Threshold input. However, some manufacturers define Attack Time as the time required to get to some point below full gain reduction, perhaps two-thirds of the total. Attack times vary from 1 to 200 milliseconds.

If the signal we’re compressing has a loud initial attack (such as a hard consonant like “t” or “k”), we may want to ensure that the attack gets through unaffected even though it’s louder than our desired average output level. In this case, we want a longer Attack Time. On the other hand, if it’s the transient that we want to sit on, we want a fast attack so that gain reduction will begin as soon as possible after the input crosses the Threshold. The Attack Time is related to, but is not the same as the shape of the compressor’s “knee.”

Once a high level signal falls back below the Threshold level, the compressor stops compressing and starts working like a piece of wire again, but this doesn’t happen instantly. Instead, the compressor’s gain changes gracefully (we hope) back to unity over some period of time. This time period is called Release Time (sometimes called Recovery Time), and is obviously controlled by the Release Time knob.

Release times can vary from 50 milliseconds to several seconds, and they are perhaps the most critical variable in compression, because the Release Time controls the moment-to-moment changes in the level and, therefore, the overall loudness. One purpose of the Release Time is to make the variations in loudness level caused by the compression imperceptible.

Generally, the Release Time should be set long enough that if signal levels repeatedly rise above the threshold, they cause gain reduction only once. If the release time is too long, a loud section of the audio could cause gain reduction that continues through a soft section.

If the Release Time is set too short, “pumping” artifacts may result. Pumping is defined as an audible, regular change, up and down, in volume of a track. It is especially noticeable with higher compression Ratios, and is considered a Bad Thing.

Another artifact of too much compression is “breathing.” If the compression Ratio is set too high, then during quiet passages the noise floor will appear to get louder. In extreme cases this sounds like someone breathing underneath the track, as the noise floor level goes up and down.

Making Up Isn't Hard To Do

Since the purpose of a compressor is to reduce gain, it is usually desirable to amplify its output after the gain reduction to get back to your system’s nominal operating level. Most compressors have an Output or Make-Up Gain control which lets you “make up” for the overall gain reduction, so you can present a good hot signal to the next device in your recording chain.

When using a compressor, it’s useful to know how much gain reduction it’s doing. Most compressors are equipped with a meter, which looks like a VU meter but appears to work backwards. A typical compressor meter will read 0 dB when the input is below Threshold and moves down scale as the input level goes beyond Threshold and the compressor starts doing its thing. When the meter reads -6 this represents a gain reduction of 6 dB.

Often there’s a separate meter or a switch to allow the gain reduction meter to read input level as a guide to setting the Threshold. And some compressors also allow you to monitor the output level so you’ll know when you’re in danger of running out of headroom.

Variables Inside the Box

On the surface, a compressor appears to be a fairly simple device. All the action takes place in a gain control element with an amplifier on the front and back end to match up signal levels to the outside world. There are several different devices that are used as a variable gain element, and to a large extent, it’s the characteristics of the different devices that give each different compressor its “personality.”

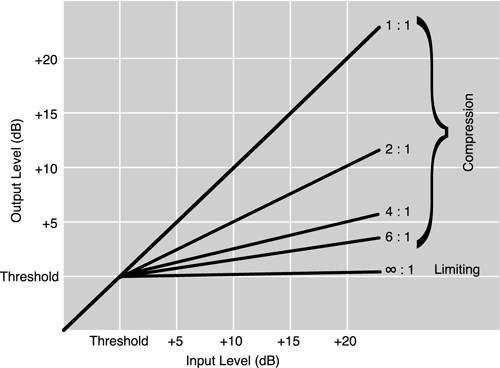

There are two paths in a compressor, the main audio path and the side chain (see figure 3). The audio path is what you put in and what you expect to get out. But in order to derive a voltage used to adjust gain, the input signal must be detected and applied to the gain control input of whatever element is used for gain reduction. This path is called the side chain.

We aren’t interested in following the input waveform cycle by cycle, but rather, want our control voltage to follow the overall level, or envelope, of the waveform. The method in which the side chain control voltage is derived is another contributor to the compressor’s personality. Manufacturers have used simple averaging detectors, peak level detectors, and true RMS average detectors. Each will give control voltage that follows the input signal a little differently, so each type of side chain detector will impart a different control action on the main audio signal. In addition, designers have applied their own “corrections” to the side chain signal to compensate for non-linearity of the gain control element.

There is more than one method of detecting the level of an input signal as well. In a feed forward design, the input signal goes to the side chain detector. In a feed back design, the output of the gain control element is fed back through the detector to control the gain. Again, each has its own personality in terms of response time.

As mentioned, the compressor will respond differently depending on whether it is monitoring the input signal in either PEAK or RMS mode. Some compressors allow you to switch between PEAK and RMS operation.

The PEAK setting makes the compressor reduce any signal rising above the Threshold, no matter how fast the transient. This is an ideal mode to use for something like digital recording, where you need to absolutely stop any signals from overloading the input and causing digital distortion. However, Peak compression can sound unnatural and can produce noticeable artifacts unless you use a low compression Ratio.

RMS compression is generally more natural sounding. RMS mode doesn’t bother with quick short peaks that might cut through above the average signal level, even if you set a fast Attack Time. RMS mode works on a wider average than PEAK mode, thus allowing some fast transients through, but closing down more when continuous loud peaks appear.

Gain Elements

Several of the “classic” compressors use a photocell (light dependent resistor or LDR) as a variable resistor in a voltage divider. An incandescent light bulb, LED, or electroluminescent (EL) panel glued to the photocell is driven by a voltage that’s derived from the level of the input signal (not the input signal itself). The actual signal goes through the LDR. The light gets brighter as the signal gets louder, causing the photocell to change resistance and, in essence turn a pot to reduce the gain. A Vactrol (R) is a sealed module consisting of a light source and LDR that was used in several “classic” compressors, and today you’ll sometimes see the term “Vactrol” associated with a certain flavor of compression.

Another gain control element is a vacuum tube used as a variable resistor, lending the name “Variable-mu” (mu is the symbol used for the tube’s gain) to yet another style of compressor. The classic variable-mu compressor is the Fairchild 670, now selling on the vintage market for over $10,000! Altec also made one, and today, Manley Labs builds one using the same principle of gain control, but with a different tube and making use of a full differential signal path, which cancels out second harmonic distortion caused by the tube’s action.

VCA compressors are most common today due to the availability of expensive and reasonably good VCAs in IC form. Since this style of VCA is all on one chip, the designer’s challenge is to keep the signal that’s controlling the gain out of the actual audio signal path. New designs are pretty successful, and offer the most positive control of gain vs. control voltage. The VCA is the fastest responding and most linear (or rather, most predictable) gain control element, so it lends itself well to the new breed of digitally controlled analog compressors. Here, the side chain control voltage can be shaped digitally to produce any imaginable response curve, allowing the compressor’s gain control element to emulate the sound of any “classic” which can be measured.

VCA-based compressors typically allow higher “limiting” ratios than optical units (remember, compressing above 10:1 is generally considered limiting), but they can sound dull or flat due to the “stonewalling” of signals above a predetermined level.

Optical compressors are generally more expensive, less flexible, and sometimes more difficult to use than their VCA-based counterparts, and their input level, Ratio, Threshold, and time settings are less precise. But optical units typically exhibit less distortion and noise than VCA models. The relationship between the functions is more complex and interrelated in optical compressors, making them all the more dependent on the judicious ear of the user for optimal results.

Defining a Compressor's Sound

Just about everything inside the box affects the sound of a compressor — the gain control element, the way the side chain signal is derived and processed, the sound of the amplifiers in the input and output, and even the power supply. Today’s much lusted-after “tube compressor sound” is really a new development. Of the much-emulated classic compressors, only the Teletronix LA-2 had tube amplifiers. All the newer models in the series were solid state although they used the same basic (with seasonal variations) gain control elements. Much of what we think of as the warm tube sound of a compressor is a result of a tube input and/or output stage, not the compressing action itself. Certain compressors have a reputation for creating irregularities in frequency response, both favorable and unfavorable, but this in general isn’t a result of gain reduction, but rather, input and output stages.

To complicate matters still further, pan pots on audio gear have rather generous tolerances — as much as five or ten percent. In other words, the numbers won’t necessarily translate exactly from one box to the next. On top of that, every compressor has its own sonic personality. Use your ears and tweak the settings to taste.

Recently, all-digital compressors have appeared, often as part of a comprehensive digital processor or digital mixing console. Digital compressors function just like analog compressors, except that instead of using a VCA or optical device to ride the gain, digital compressors use DSP chips and sophisticated software algorithms to accomplish their magic on digital audio signals. Purists contend that they can hear the difference between analog and digital compressors, but these differences are certain to become less apparent as the algorithms improve.

Another new category of compressors is the so-called Multiband compressor. This beast uses filters to split the input signal into a number of different frequency bands, and then lets you compress the bands independently. While used primarily for mastering music, Multiband compressors can help tame wild top- or bottom-end peaks without affecting the rest of the frequency range, and without changing the overall EQ balance of the track.

Stupid Compressor Tricks

Many compressors have a side chain input that allows you to patch into the side chain and substitute a different signal to control the gain element. This lets us have some fun with the compressor and change its character.

You can use one track to “duck” another. If you run a music bed through a compressor, and feed a VO track into the side chain input, the compressor will reduce the music volume in response to the VO level. You may need to experiment with attack and release times to ensure that the music volume doesn’t pump up and down noticeably, but this technique can be effective.

You can get a very good single channel De-esser from a compressor. Split a VO track, and send it to the compressor and also to a spare channel. EQ the daylights out of that second channel, boosting the 5 or 6 kHz band and chopping everything below that. Use the insert send from this second channel to feed the side chain input. This will cause the compressor to respond only to peaks in the 5 or 6 kHz band, turning it into a De-esser.

Remember here that no matter what you cut or boost on the EQ, the compressor is going to always act on the whole signal. Don’t get confused and think that boosting 4k on the side chain is going to “compress” 4k in the VO. It only makes the whole device more sensitive to that frequency; what it does with that sensitivity still happens to the whole signal.

Squeeze, Don't Squash

Although it’s tempting to compress the daylights out of your commercial spot to make it sound commanding, you’ll often end up squeezing all the life out of it. Add to that the fact that the broadcast chain introduces its own heavy compression, and you have the potential for some Seriously Bad Sound.

How do you make sure that your mix will still sound good at the transmitter? One suggested method is to patch a compressor into the monitor mix only, and set it to mimic the compression that normally occurs between the console and the transmitter. In this way you’ll hear a good approximation of what will actually go to air, and can adjust your mix elements and their compression accordingly.

♦